Municipal water systems battling iron and manganese contamination face costly operational nightmares beyond visible staining—from bacterial slime clogging pipelines to skyrocketing energy costs. But one proven treatment combination consistently delivers results where others fail.

Key Takeaways

- Chemical oxidation combined with filtration remains the most reliable method for treating iron and manganese concentrations above 10 mg/L in municipal water systems

- Manganese greensand filters excel for moderate contamination levels (3-10 mg/L combined) with proper potassium permanganate regeneration protocols

- Water testing determines treatment selection—EPA secondary standards limit iron to 0.3 mg/L and manganese to 0.05 mg/L

- Municipal case studies demonstrate that horizontal pressure filters with specialized media can reduce operational costs while maintaining effective treatment

- System design factors, including chlorination strategies and pressure management, prevent iron-manganese bacterial growth that creates pipeline slime

Iron and Manganese Create Critical Water Quality Issues Beyond Staining

What problem does Hydrologics ZDF technology solve?

Municipal water systems face constant challenges with iron and manganese contamination that extends far beyond the visible reddish-brown and black stains on fixtures and laundry. These metals create operational nightmares for water treatment plant engineers through decreased water pressure, increased energy costs, and the formation of bacterial slime that clogs distribution systems. Iron and manganese deposits accumulate in pipelines, pressure tanks, and water heaters, forcing pumps to work harder and driving up operational expenses across entire municipal networks.

The financial impact multiplies when considering the customer complaints, infrastructure damage, and regulatory compliance issues that arise from untreated iron and manganese. Municipal operators know that even concentrations below health concern levels create aesthetic problems that erode public confidence in water quality. Hydrologics addresses these challenges through proven water treatment technologies that municipal engineers rely on for consistent, cost-effective results.

Why are iron and manganese so difficult to remove from water mains?

The complexity of iron and manganese removal stems from their ability to exist in multiple chemical forms within water distribution systems. Dissolved iron and manganese remain invisible until exposed to oxygen, where they rapidly oxidize and precipitate into solid particles. This transformation occurs unpredictably throughout distribution networks, creating inconsistent treatment challenges that vary by location, pH levels, and contact time with atmospheric oxygen.

Iron and manganese bacteria compound these difficulties by feeding on the dissolved metals and forming persistent biofilms throughout pipeline systems. While these bacteria don’t pose direct health risks, their presence can indirectly affect water quality by creating dense, slimy deposits that resist standard cleaning methods and provide ongoing sources of contamination. The bacteria can colonize even treated water systems, making complete elimination nearly impossible without continuous treatment protocols.

How does Hydrologics Zero Discharge Flushing System Work?

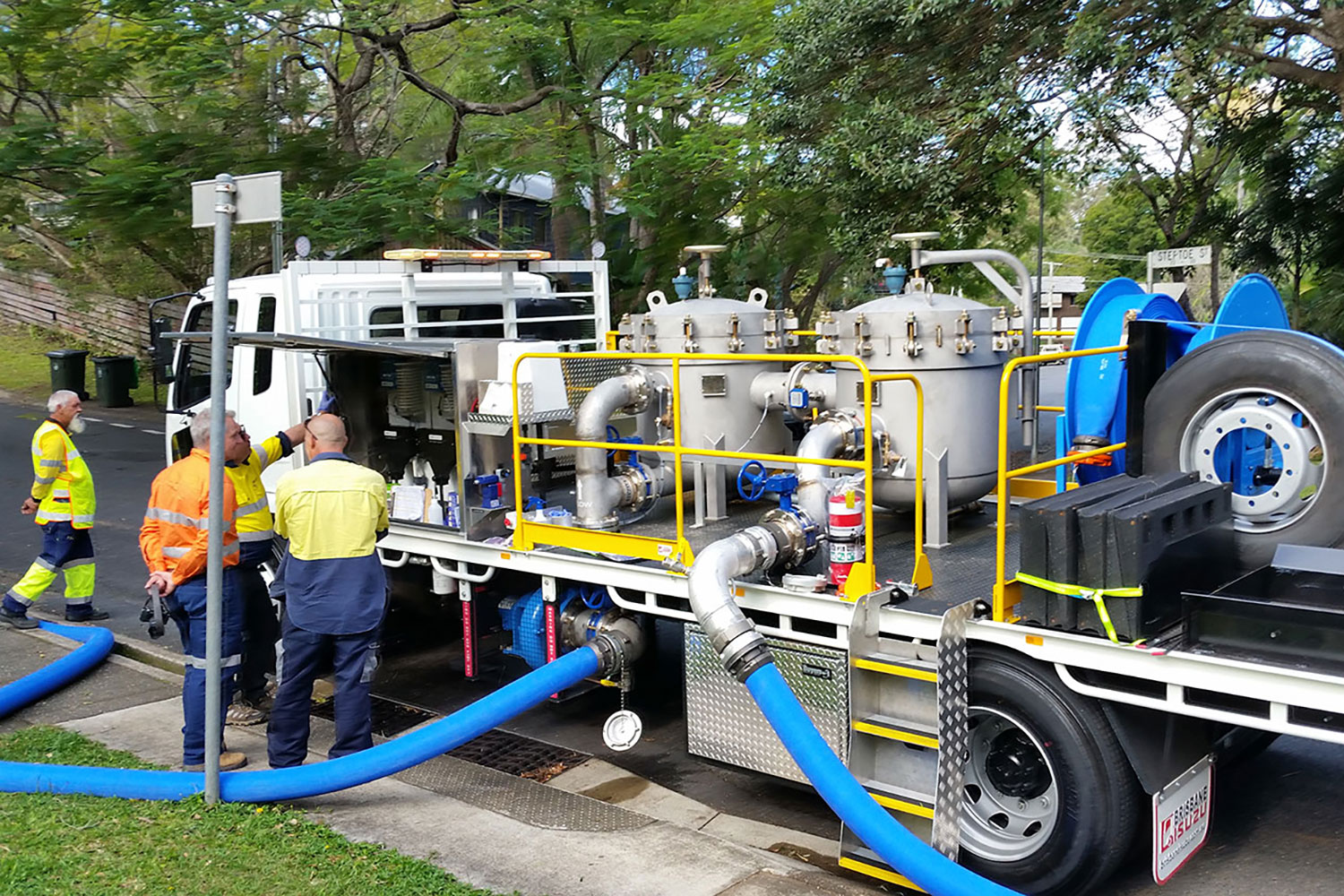

Zero Discharge Flushing (ZDF) technology transforms traditional main cleaning by eliminating the need to discharge contaminated water during iron and manganese removal processes. The system captures and treats flushing water on-site, allowing municipalities to clean distribution mains without losing treated water or creating environmental discharge concerns. This closed-loop approach maintains water pressure while effectively removing accumulated iron and manganese deposits from pipeline interiors.

The ZDF system utilizes high-velocity water movement combined with specialized filtration to dislodge and capture iron and manganese particles, bacterial slime, and other accumulated debris. Unlike conventional flushing that wastes thousands of gallons of treated water, ZDF technology recycles the cleaning water through multiple filtration stages, returning clean water to the distribution system while containing all removed contaminants for proper disposal.

Can you give an example of Zero Discharge Flushing technology in action?

Municipal water systems using ZDF technology often report improvements in water quality metrics and customer satisfaction scores within weeks of implementation. The technology proves particularly effective in older distribution networks where decades of iron and manganese accumulation have created chronic pressure and quality issues. Operators appreciate the ability to clean mains without coordinating complex water shutoffs or managing environmental discharge permits.

Field applications demonstrate ZDF’s effectiveness across various pipe materials and contamination levels. The system adapts to different main sizes and configurations while maintaining consistent removal rates for iron and manganese deposits. Municipal engineers value the operational flexibility and reduced regulatory burden compared to traditional flushing methods that require discharge permits and waste-treatment protocols.

Chemical Oxidation Provides Reliable Treatment for High Concentration Scenarios

1. Chlorine vs. Alternative Oxidants for Different Conditions

Chemical oxidation represents the gold standard for treating combined iron and manganese concentrations exceeding 10 mg/L in municipal water systems. Chlorine remains the most widely used oxidizing agent due to its availability, cost-effectiveness, and dual function as both an oxidant and disinfectant. Sodium hypochlorite injection systems provide reliable oxidation of dissolved iron at pH levels between 6.5 and 7.5, converting invisible dissolved metals into filterable solid particles.

However, chlorine shows limitations with high manganese concentrations, requiring pH levels above 9.5 for complete oxidation—conditions that create their own operational challenges. Potassium permanganate emerges as the superior choice for manganese oxidation at pH levels above 7.5, though it demands careful handling due to its toxic nature and requires precise dosing to avoid excess chemical in treated water. Hydrogen peroxide offers an environmentally friendly alternative but typically costs more than traditional oxidants and may require specialized injection equipment.

2. Contact Time Requirements for Complete Oxidation

Effective chemical oxidation demands minimum contact times of 20 minutes for standard iron and manganese concentrations, with longer periods required for colloidal forms or when iron combines with organic matter. Municipal treatment plants achieve proper contact time through mixing tanks, coiled pipe sections, or dedicated contact basins that allow complete chemical reactions before filtration stages. Insufficient contact time results in incomplete oxidation and breakthrough of dissolved metals into the distribution system.

Contact time calculations must account for water temperature, pH, and the presence of interfering substances that consume oxidizing chemicals. Cold water requires longer contact periods, while organic matter in raw water increases chemical demand and extends necessary reaction times. Treatment plant operators monitor oxidation effectiveness through residual testing and particle formation indicators that confirm complete metal precipitation before filtration.

3. pH Optimization and THM Formation Considerations

pH optimization balances effective metal oxidation against the formation of disinfection byproducts, particularly trihalomethanes (THMs) that create regulatory compliance issues. Iron oxidizes efficiently across a wider pH range than manganese, allowing operators more flexibility in system optimization. However, high pH conditions required for manganese oxidation may accelerate THM formation when chlorine contacts organic matter in raw water.

Municipal systems address THM concerns through strategic pH adjustment, alternative oxidant selection, or enhanced organic matter removal before oxidation. Some facilities employ sequential oxidation processes, treating iron first at optimal pH levels, then adjusting conditions for manganese removal. Advanced treatment plants integrate pH monitoring and automatic adjustment systems that maintain optimal conditions for metal oxidation while minimizing disinfection byproduct formation.

Manganese Greensand Filters Excel for Moderate Levels (3-10 mg/L Combined)

Potassium Permanganate Regeneration and Pink Water Prevention

Manganese greensand filters provide exceptional performance for moderate iron and manganese concentrations through a unique oxidation-filtration process that occurs within the filter media itself. The greensand material, coated with manganese oxide, simultaneously oxidizes dissolved metals and captures the resulting particles in a single treatment step. This dual action makes greensand particularly effective for municipal applications where combined iron and manganese levels range from 3-10 mg/L.

Potassium permanganate regeneration maintains the oxidizing capacity of greensand media but requires careful management to prevent the dreaded “pink water” incidents that plague municipal systems. Proper regeneration protocols call for precise permanganate dosing based on media volume and contamination levels, followed by thorough rinsing to remove excess chemical. Municipal operators must establish strict regeneration schedules and monitoring procedures to prevent permanganate breakthrough that creates customer complaints and regulatory issues.

Maintenance Schedule and Cost Analysis

Successful greensand filter operations depend on rigorous maintenance schedules that balance treatment effectiveness against operational costs. Weekly backwashing removes accumulated oxidized particles, while monthly permanganate regeneration restores the media’s oxidizing capacity. Municipal facilities typically schedule regeneration during low-demand periods to minimize service disruptions and allow proper contact time for media conditioning.

Cost analysis reveals that greensand systems offer favorable economics for moderate contamination levels compared to more complex oxidation-filtration combinations. Initial media costs and regeneration chemical expenses must be weighed against reduced operational complexity and lower labor requirements. Municipal budget planning should account for annual media replacement, permanganate consumption, and periodic equipment maintenance to ensure long-term treatment reliability.

Water Testing Determines Treatment Method Selection

Dissolved vs. Oxidized Form Detection

Accurate water testing forms the foundation of effective iron and manganese treatment selection, requiring analysis that distinguishes between dissolved and oxidized forms of these metals. Dissolved iron and manganese appear invisible in freshly drawn water samples but form visible particles when exposed to atmospheric oxygen during storage. Laboratory testing protocols must account for this oxidation potential through immediate sample preservation or on-site analysis techniques.

Field testing procedures help municipal operators understand the practical behavior of iron and manganese in their specific water systems. Simple jar tests demonstrate oxidation rates and particle formation characteristics that influence treatment method selection. Water samples that remain clear after 24 hours of atmospheric exposure contain primarily dissolved metals suitable for chemical oxidation or ion exchange treatment, while immediate particle formation indicates oxidized metals requiring filtration approaches.

EPA Secondary Standards: 0.3 mg/L Iron, 0.05 mg/L Manganese

EPA secondary maximum contaminant levels establish treatment targets of 0.3 mg/L for iron and 0.05 mg/L for manganese, based on aesthetic considerations rather than health concerns. These standards guide municipal treatment decisions and customer satisfaction goals, though many systems target lower concentrations to prevent staining and taste complaints. Understanding that secondary standards focus on aesthetic rather than health impacts helps municipal managers prioritize treatment investments and establish realistic performance expectations.

Regulatory compliance requires consistent monitoring and documentation of iron and manganese levels throughout the distribution system. Municipal systems must establish sampling protocols that account for seasonal variations, source water changes, and distribution system effects on metal concentrations. Regular testing at multiple locations helps identify treatment effectiveness and potential distribution system contributions to metal contamination.

Proven Municipal Case Studies Show Cost-Effective Solutions

Pottawatomie County’s WesTech Horizontal Pressure Filter Success

Pottawatomie County’s transition from cartridge filtration to horizontal pressure filters demonstrates the operational and economic advantages of proven municipal iron and manganese treatment technologies. The county replaced high-maintenance cartridge systems with WesTech horizontal pressure filters using specialized ANTHRA/SAND media, achieving significant cost savings while reducing operator workload and maintenance requirements.

The horizontal pressure filter design provides superior backwashing efficiency and media utilization compared to vertical configurations, particularly important for municipal systems processing large volumes of contaminated water. Pottawatomie County’s experience shows that proper filter sizing and media selection can eliminate the frequent cartridge replacements that drain municipal maintenance budgets while providing more consistent treatment performance across varying source water conditions.

ANTHRA/SAND Media Conditioning and Performance Data

ANTHRA/SAND media conditioning protocols proved critical to Pottawatomie County’s treatment success, requiring specific preparation procedures that optimize media performance for iron and manganese removal. The dual-media configuration combines anthracite coal’s physical filtration properties with the manganese oxide coating on sand that provides chemical oxidation capabilities, creating effective treatment across a broad range of contamination levels and water chemistry conditions.

Performance monitoring data from the Pottawatomie County installation demonstrates ANTHRA/SAND media’s effectiveness compared to traditional GreensandPlus alternatives. Pilot study results showed equivalent removal efficiency with lower maintenance requirements and extended media life, translating into substantial operational savings for municipal operators. The success of this media combination has influenced treatment design decisions at other municipal facilities facing similar iron and manganese challenges.

System Design Factors That Prevent Iron-Manganese Bacterial Growth

Chlorination Strategies for Pipeline Slime Control

Strategic chlorination prevents iron and manganese bacteria colonization in distribution systems through maintaining residual disinfectant levels and periodic shock treatments that disrupt biofilm formation. Municipal systems require careful balance between sufficient chlorine residual for bacterial control and excessive levels that create taste and odor complaints or disinfection byproduct formation. Effective chlorination strategies target bacterial nutrients while maintaining water quality standards throughout the distribution network.

Shock chlorination procedures provide intensive bacterial control when routine chlorination proves insufficient for preventing biofilm development. These treatments require coordinated system-wide chlorine application, followed by extensive flushing to remove dislodged bacterial slime and restore normal chlorine residuals. Municipal operators must plan shock treatments carefully to minimize customer impacts while achieving complete bacterial elimination in affected pipeline sections.

Pressure Reduction and Health Risk Mitigation

Iron and manganese deposits reduce pipeline capacity and create pressure variations that can compromise distribution system integrity and create public health risks through cross-connections and backflow incidents. Accumulated deposits act as flow restrictions that force pumping systems to work harder while creating pressure zones where bacterial growth thrives in low-flow conditions.

Pressure management strategies must account for the cumulative effects of metal deposits throughout the distribution network, requiring regular assessment of system capacity and pressure profiles. Municipal engineers use pressure monitoring data to identify sections requiring cleaning or treatment, preventing progressive deterioration that could compromise service reliability or create regulatory compliance issues. Proactive deposit removal maintains system hydraulics and reduces long-term infrastructure replacement costs.

Chemical Oxidation Combined with Filtration Flushing Delivers Consistent Municipal Results

The integration of chemical oxidation treatment with strategic distribution system flushing creates the most effective approach to municipal iron and manganese control. This combined strategy addresses both source water treatment and distribution system maintenance, preventing the accumulation of deposits that compromise water quality and system performance. Municipal systems implementing integrated approaches report superior long-term results compared to treatment-only or flushing-only programs.

Coordinated treatment and maintenance schedules optimize chemical usage while maintaining consistent water quality throughout the distribution network. Chemical oxidation handles dissolved metals at the treatment plant, while systematic flushing removes accumulated deposits and bacterial growth from pipeline interiors. This dual approach prevents the gradual deterioration of water quality that occurs when treatment alone cannot address distribution system contamination sources.

Municipal operators benefit from simplified monitoring and maintenance protocols when oxidation and flushing strategies work together synergistically. Treatment plant optimization reduces the burden on distribution system cleaning, while effective pipeline maintenance extends the life of treatment equipment and reduces chemical consumption. The result is a sustainable approach to iron and manganese control that balances operational costs against long-term system reliability and customer satisfaction.

For iron and manganese treatment solutions that municipal engineers trust, contact Hydrologics to learn about proven water treatment technologies designed for municipal applications.